The securement of the annular link mechanism to the rim and the roof is such as to permit articulation of the annular link mechanism relative to the rim and roof to a point of failure of the joint.

Frangible roof weld.

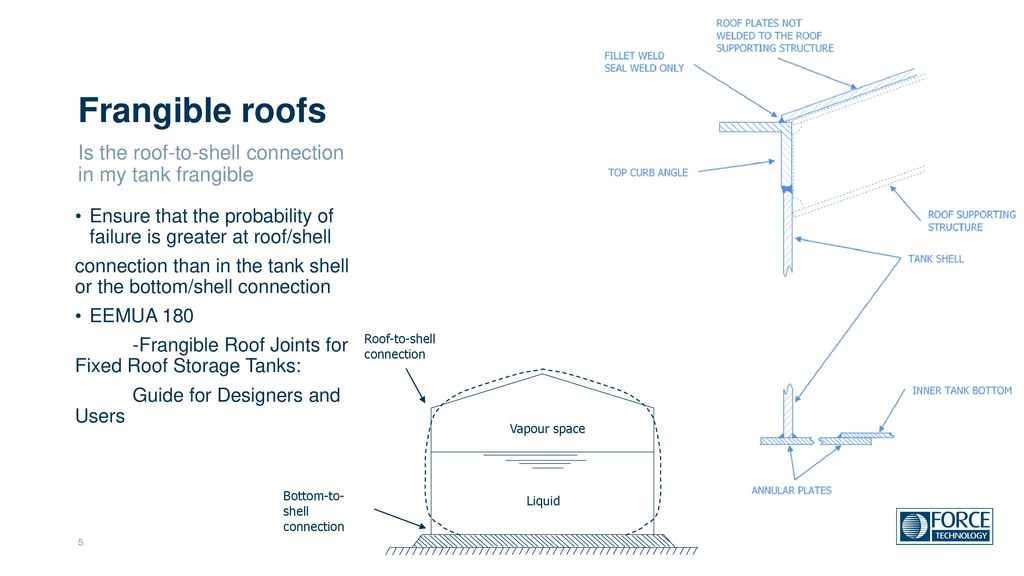

In such tanks the roof to shell joint is intended to fail in the event of overpressurization venting the tank and containing any remaining fluid.

This paper presents the results of an investigation into the frangible joint behavior of tanks designed to api 650 rules.

The reasoning behind present api design formulas is reviewed.

However in the context of tanks the word has a specific meaning and is defined in the main tank construction standards bsen 14015 and api650.

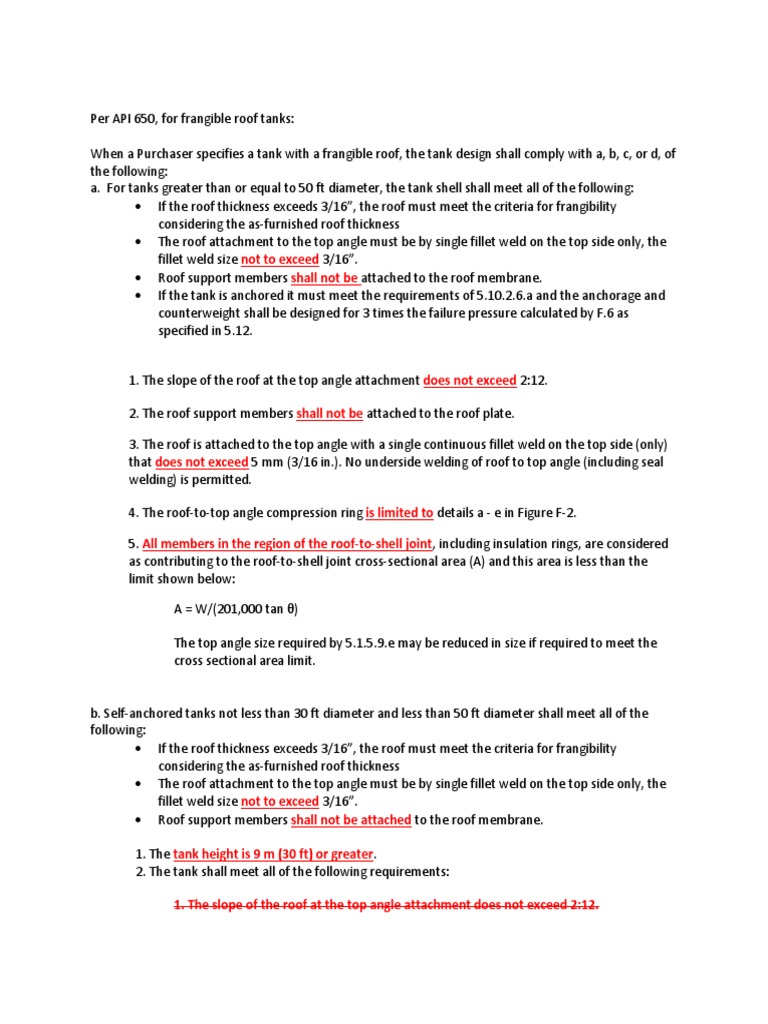

Such joint is practically sacrificial weld which has to collapse in event of excessive internal pressure while shell to bottom joint has to be undamaged to provide structural and safe integrity of tank.

This failure is intended to vent the tank and contain any remaining fluid.

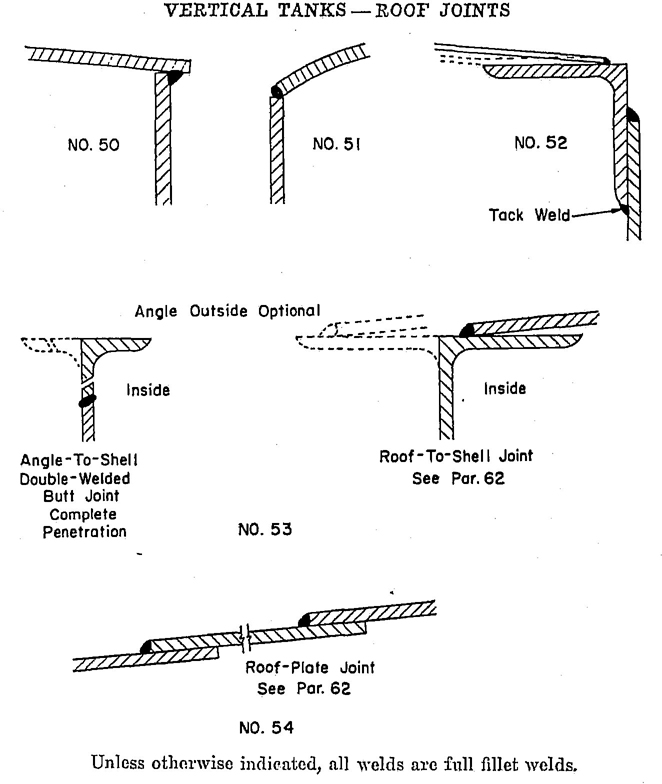

The api 650.

In the event of over pressurization the frangible roof to shell joint is designed to fail before the tank shell or the shell to bottom joint.

One of the safety measures that can be employed for emergency venting is so called frangible roof to shell joint.

This video documents the research and testing on frangible joint storage tanks performed at kansas state university and thunderhead engineering.

Frangible is a word that means easily broken.

Api 650 gives rules for the design of frangible roof joints in fluid storage tanks.

A small diameter tank which comprises a shell having a rim at its upper edge a roof and a frangible roof joint the roof joint including annular link means sealingly secured at or adjacent a.

A frangible roof joint forming a flexible gastight connection between a tank shell and a roof comprising an annular link mechanism sealingly secured at or adjacent a first edge thereof to a rim of the tank and sealingly secured at or adjacent a second edge thereof to the periphery of the roof.