Since vinyl alcohol is highly unstable with respect to acetaldehyde the preparation of vinyl acetate is more complex than the synthesis of other acetate esters.

Ethylene vinyl acetate boiling point.

Poly ethylene co vinyl acetate 4 product results.

The major industrial route involves the reaction of ethylene and acetic acid with oxygen in the presence of a palladium catalyst.

Chemsrc provides ethylene vinyl acetate copolymer cas 24937 78 8 msds density melting point boiling point structure formula molecular weight etc.

Vinyl acetate is the acetate ester of vinyl alcohol.

Ethylene vinyl acetate is a type of plastic a polymer with a wide variety of uses both residential and industrial.

Also it imparts plastic like properties that enable wax to compete effectively with high quality polymeric coatings.

Emblem in packaging technology 2012.

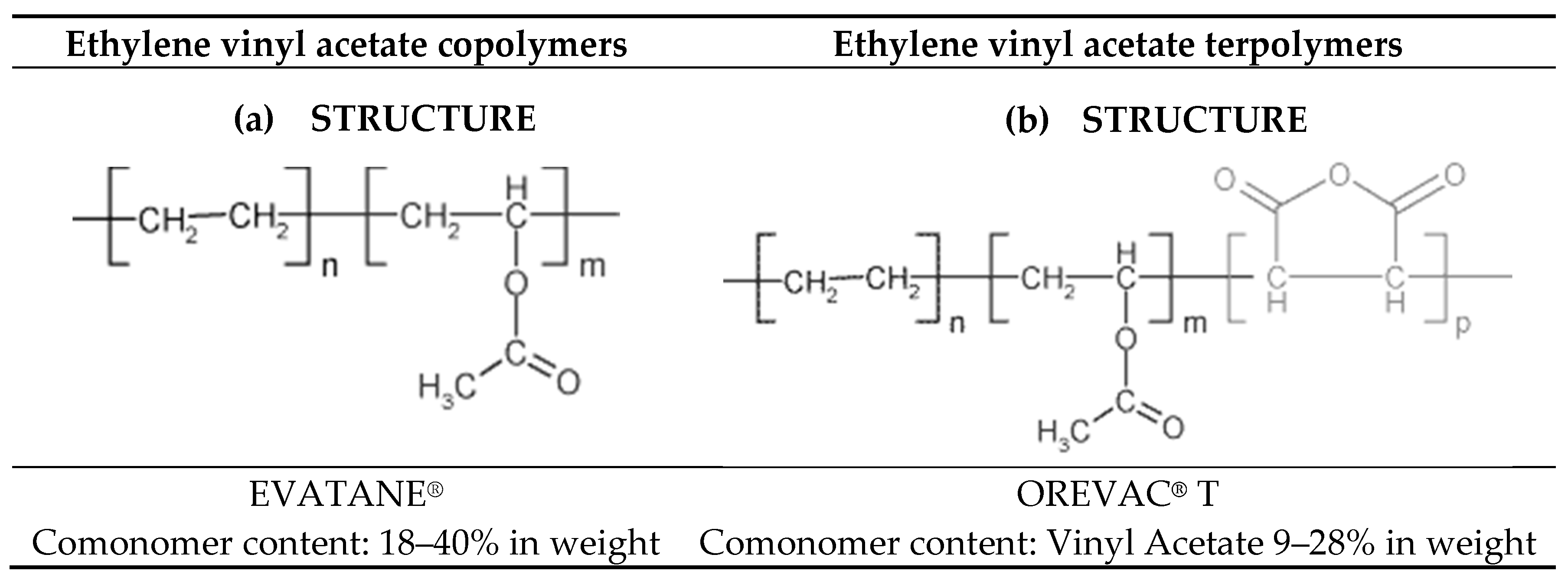

Ethylene vinyl acetate eva also known as poly ethylene vinyl acetate peva is the copolymer of ethylene and vinyl acetate the weight percent of vinyl acetate usually varies from 10 to 40 with the remainder being ethylene.

Eva ethylene vinyl acetate this copolymer resin can be used in adhesives sealants and coatings.

The food and drug administration fda has stated that ethylene vinyl acetate is safe when used in food production packaging or transportation and it s not an especially dangerous material.

Boiling point c 0 100 1 101 200 1 melting point c 0 100 5 color.

Gas chromatography gc 1 hplc 1.

Articles of vinyl acetate are included as well.

As the va content increases crystallinity decreases until at 50 the eva is.

Articles of ethylene vinyl acetate copolymer are included as well.

Chemsrc provides vinyl acetate cas 108 05 4 msds density melting point boiling point structure formula molecular weight etc.

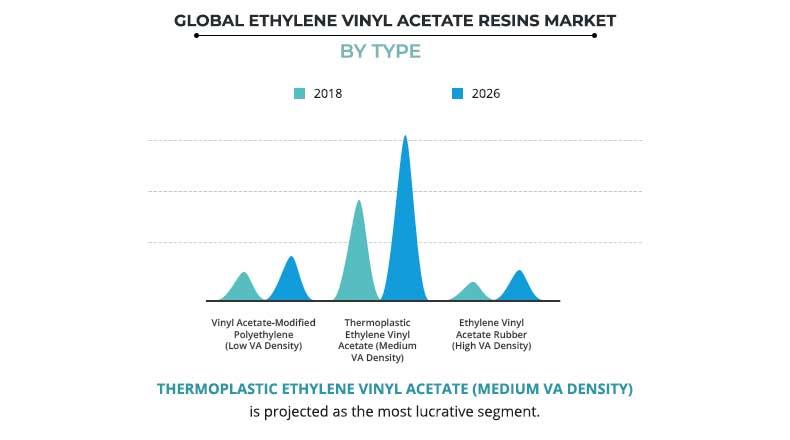

There are three different types of eva copolymer which differ in the vinyl acetate va content and the way the materials are used.

Ethylene vinyl acetate eva is a random copolymer of ethylene and varying amounts of vinyl acetate va.

.jpg)